Trusted Quality:

TransTec® Radial Shaft Seals

Not All Shaft Seals are the Same — Know How to Identify the Problems

Leaks can occur when your seal has a poor lip design, and can be compounded by poor manufacturing processes and lower cost materials. Lack of pumping action from a poorly designed helix, and an overly tight I.D. can also be detrimental to a good seal. Many technicians believe a tighter fit is a better sealing product. The truth is, an overly tight fit often means the seal will fail prematurely due to increased friction. Be aware of the warning signs:

An increase of friction, generates heat and reduces the pumping action of the seal.

The combination of friction, heat and reduced pumping actions, causes “coking” to occur; the liquid oil turns into a solid residue.

Coking affects the pumping action of the seal, and in turn, results in extra wear and a shorter life span of the seal.

Testing Proves TransTec® Shaft Seals from Freudenberg-NOK are Superior in Quality and Dependability

Product Testing Results

A side by side comparison shows that the competitor’s seal wore 5X’s more than the Freudenberg-NOK seal when put through standard seal testing required by major manufacturers such as GM, Ford, and FCA.

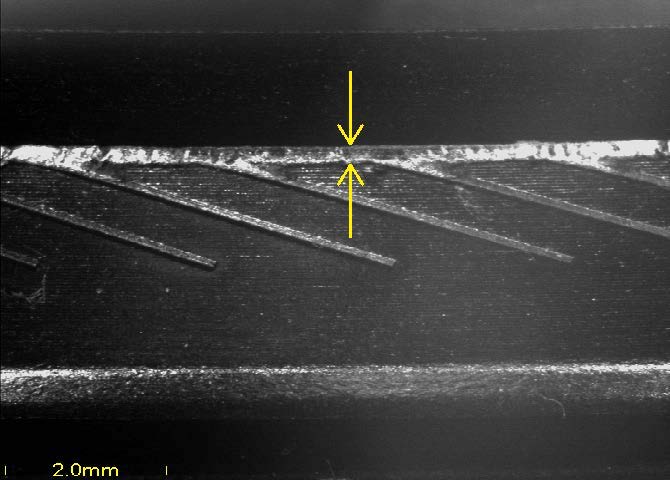

TransTec®

Lip Wear Into Helix Bars = 0.27 mm

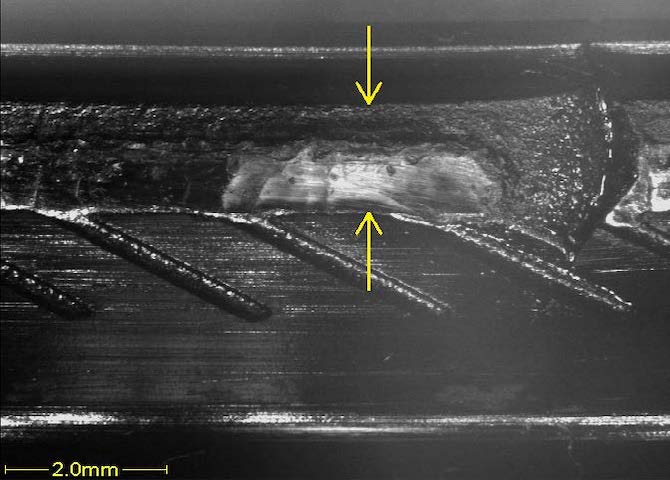

Competitor

Lip Wear Into Helix Bars = 1.51 mm

With Radial Shaft Seals, You Get What You Pay For

TransTec® Radial Shaft Seal from Freudenberg-NOK

- Designed, engineered and manufactured to create the best seal performance and longevity

- Knife trim lip which has less chance of leaking, especially at initial use

- Even and consistent helix contact with the shaft for maximum fluid pumping

Competitor Radial Shaft Seal

- Uses a molded lip – which has a higher tendency to initially leak

- Smaller inner diameter of the seal causes a tighter fit on the shaft, causing accelerated wear

- Helix contact with the shaft is not consistent

Professional Automatic Transmission Seal Kits and Tools

TransTec® automatic transmission seal kits continue to be produced with the same high quality and dependability as when the brand debuted in the automotive aftermarket in 1978. As a brand of Freudenberg-NOK Sealing Technologies, the world’s largest producer of sealing products, TransTec® is the only aftermarket overhaul kit brand that is both an original equipment manufacturer and holds ISO-9000 certification. These are just a few of the many reasons why more transmission professionals install TransTec® kits than all other brands combined.

TransTec® Transmission Seal Kits available worldwide

TransTec® brand transmission seal kits have been supplied to the automotive aftermarket since 1978 and are available through distributor all around the globe.

Need to ID the Transmission in a Specific Vehicle?

Access the TransTec® Online Transmission Application Guide — the original guide to automatic transmissions by vehicle.

Check Out Our Blog

Backed by over 35 years of technical and practical expertise and experience in the automotive aftermarket, The TransTec Blog is where today’s transmission rebuild and power steering rebuild shops and professionals can learn more about the technologies and processes that drive the industry.